Once unzipped, mpcnc.cps can be installed using F360 Manage->Post Library. Here is a copy of Flyfisher604 v2.1 for easy reference Fusion 360 & Inventor CAM (HSM) users, you have access to the post.

#Fusion 360 post processor install#

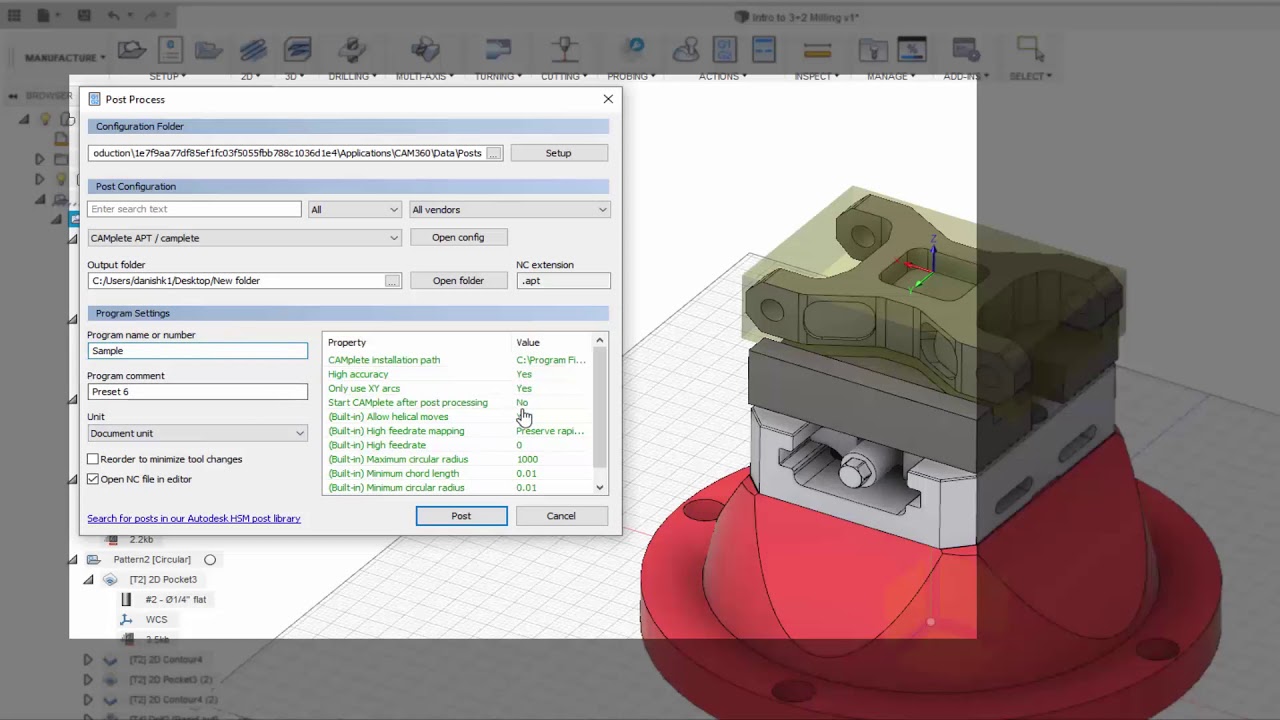

Single file install via F360 standard Manage->Post Library install interface.

Firmware dialect selected as a property.SafeZ (G1 to G0 conversion) can reference the Heights defined in a tool operations.Coolant channels reworked allows for channels A and B to be enabled at the same time allows a coolant type to be defined for a laser coolant properties are unified to control either Marlin and Grbl firmware warnings if tool’s requested coolant is not configured on a channel.Bugfix: Undefined variable used for Z height during toolchange, garbage output.Enhancement: Custom gcode for coolant channels can be defined.I'm going to try using it like this for a bit, I haven't used it to run a machine yet, so keep yer finger on the E-stop button until you've run a test program.Release V2.1 of the Flyfisher604 F360 post processor is available. Fine for my purposes, I'll just put a conservative tolerance zone in there.) I'm fine with that, though it will undoubtedly cause some confusion. (I am aware that this will actually result in a tolerance zone of double the input tolerance value. So I made it post out a G64 P0.0x block on every operation, which inherits the Tolerance value from that operation. What we're really talking about is the overall tolerance of the operation, and a lot of operations which may need tight tolerance machining at high speeds may not have a Smoothing parameter, or you may not want to use Smoothing just to get your machine to not round corners under acceleration. I was going to start with Spangled's post, because I was going to have an overall G64 P0.0x value, combined with a per-operation G64 P0.0x value based on if the operation has a "smoothing" parameter applied.īut then I thought, that's not really what the smoothing is for. Check the output before running it on a physical machine!

#Fusion 360 post processor code#

In the thread mentioned above, it was suggested that a different P value would be useful for roughing/adaptive moves, which makes sense, however this is more challenging to code - particularly as I'm not a developer - it took me a while to work out what's going on in the post to get this much done!Īll modified or added lines have been commented with //Spangled - search for these to check what I've done.Īs usual, you test this file at your risk - it's not my fault if your machine crashes or your house catches fire etc. Let me know if this is useful and if you have any comments. , here is a copy of the Fusion 360 Post Processor, which I have modified as follows:ġ) Added G64 to G Code preamble - can be enabled or disabled from the Fusion 360 Post Process dialogue as shown below.Ģ) Added the P value for G64 - this can also be modified from within the dialogue.ģ) Added DEBUG command into tool comment during tool change so notification box pops up on the screen prompting for the tool to be used.

0 kommentar(er)

0 kommentar(er)